UNIFREM 400 is the latest generation of frequency converters family. UNIFREM 400 is made for 3 x 400 V supply, available up to 90 kW. All UNIFREM converters allow vector control of both induction and synchronous motors and high performance scalar (V/f) control as well. They are designed to solve any drive problem in the most cutting-edge applications. The family is specified by its user-friendly settings and control, users are guided by the graphic control panel (UNIPANEL). The latest generation of MITSUBISHI and SEMIKRON power electronics has been used for minimization of losses while allowing higher switching frequency. Grid disturbance is kept to a minimum.

All drives are also available in VF version - for high-speed or special motors up to 3000Hz. UNIFREM VF converters allow independent setting of both output voltage and output frequency.

Features and advantages of UNIFREM

Output motor chokes are used in case when the distance between the converter and the motor is higher than 100m (non-shielded cable) or 50m (shielded cable).

Cable capacitance effects are eliminated by the motor choke or sine filter.

Output motor chokes are used in case when the distance between the converter and the motor is higher than 100m (non-shielded cable) or 50m (shielded cable).

Cable capacitance effects are eliminated by the motor choke or sine filter.

Sine filter filters the output PWM voltage of the inverter to the sine wave of variable frequency and amplitude.

This will limit the peak current and capacitive motor insulation stress. When using the EMC sinus filter, it is not necessary to use the shielded cable.

It is necessary to set the switching frequency of IGBT power elements to at least 4 kHz, when using the Sine filter!

Sine filter filters the output PWM voltage of the inverter to the sine wave of variable frequency and amplitude.

This will limit the peak current and capacitive motor insulation stress. When using the EMC sinus filter, it is not necessary to use the shielded cable.

It is necessary to set the switching frequency of IGBT power elements to at least 4 kHz, when using the Sine filter!

UNIPANEL is universal handheld control device for the whole latest generation of VONSCH products (UNIFREM, MVE CONTROL, FOTO CONTROL, PV COMP, GSE COMP, QUATROFREM... ).

Panel may be assembled directly to the enclosure or may be connected by wire (max. length is 100m).

UNIPANEL uses CANopen as its primary communication protocol with the inverter. Maximal number of 99 devices may be connected to UNIPANEL.

User can choose which device (inverter,controlled rectifier, other product) will be controlled and monitored.

USB port serves as communication port with PC. UNIPANEL does not serve only as monitoring and configuration device, but as backup&restore manager too.

Fully graphical display shows the description and brief help to all the parameters.

All the parameters and variables may be monitored in real-time and plotted into the graph.

UNIPANEL is universal handheld control device for the whole latest generation of VONSCH products (UNIFREM, MVE CONTROL, FOTO CONTROL, PV COMP, GSE COMP, QUATROFREM... ).

Panel may be assembled directly to the enclosure or may be connected by wire (max. length is 100m).

UNIPANEL uses CANopen as its primary communication protocol with the inverter. Maximal number of 99 devices may be connected to UNIPANEL.

User can choose which device (inverter,controlled rectifier, other product) will be controlled and monitored.

USB port serves as communication port with PC. UNIPANEL does not serve only as monitoring and configuration device, but as backup&restore manager too.

Fully graphical display shows the description and brief help to all the parameters.

All the parameters and variables may be monitored in real-time and plotted into the graph.

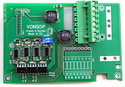

Extension module RM-UNI_IRC1 for the UNIFREM main board. Incremental encoder (IRC) is connected to the terminal marked on the IRC module.

It is used for speed, torque or position closed loop vector control. To connect to the module push-pull rotary encoder incremental encoder HTL with 24Vdc power supply is used.

Extension module contains special circuits to detect and evaluate some errors such as faulty electrical signals or disconnected encoder from the rotor.

Extension module RM-UNI_IRC1 for the UNIFREM main board. Incremental encoder (IRC) is connected to the terminal marked on the IRC module.

It is used for speed, torque or position closed loop vector control. To connect to the module push-pull rotary encoder incremental encoder HTL with 24Vdc power supply is used.

Extension module contains special circuits to detect and evaluate some errors such as faulty electrical signals or disconnected encoder from the rotor.

Extension module RM-RDC for the connection of resolver to the UNIFREM main board. The sensor is connected to the terminal marked on the module.

It is used for speed, torque or position closed loop vector control of both, synchronous and induction motors.

Extension module includes special circuits to detect and evaluate some errors such as faulty electrical signals or disconnected encoder from the motor shaft.

Extension module RM-RDC for the connection of resolver to the UNIFREM main board. The sensor is connected to the terminal marked on the module.

It is used for speed, torque or position closed loop vector control of both, synchronous and induction motors.

Extension module includes special circuits to detect and evaluate some errors such as faulty electrical signals or disconnected encoder from the motor shaft.

Profibus_UNI extension module is used for connection of the converter to PROFIBUS DP network. Profibus DP (Decentralized Peripherals) is the simple and most widely used version of Profibus

designed for fast master - slave communication.

Communication medium is twisted pair (RS-485 standard).

Profibus_UNI extension module is used for connection of the converter to PROFIBUS DP network. Profibus DP (Decentralized Peripherals) is the simple and most widely used version of Profibus

designed for fast master - slave communication.

Communication medium is twisted pair (RS-485 standard).

The RM-SERVO extension module is used to connect absolute position encoders and to interconnect multiple RM-SERVO expansion modules for multi-axis synchronization.

RM-SERVO supports several types of absolute position encoders like ENDAT, sin / cos and others.

The RM-SERVO extension module is used to connect absolute position encoders and to interconnect multiple RM-SERVO expansion modules for multi-axis synchronization.

RM-SERVO supports several types of absolute position encoders like ENDAT, sin / cos and others. | Type of the converter | M ~ variable load | M ~ constant load | Nominal input current of the converter ININ [A] | ||||

|---|---|---|---|---|---|---|---|

| Motor output rating PNOM [kW] | Nominal output current of the converter INQ [A] | Motor output rating PNOM [kW] | Nominal output current of the converter INK [A] | Nominal output current of the converter INK60 [A] | Nominal output current of the converter INK2 [A] | ||

| UNIFREM 400 011 | 11 | 24 | 7.5 | 18.1 | 27.1 | 36.2 | 23 |

| UNIFREM 400 015 | 15 | 33 | 11 | 24 | 36 | 48 | 32 |

| UNIFREM 400 018 | 18.5 | 40 | 15 | 33 | 49.5 | 66 | 38 |

| UNIFREM 400 022 | 22 | 47 | 18.5 | 40 | 60 | 80 | 45 |

| UNIFREM 400 030 | 30 | 63 | 22 | 47 | 70.5 | 94 | 62 |

| UNIFREM 400 037 | 37 | 76 | 30 | 63 | 94.5 | 126 | 75 |

| UNIFREM 400 045 | 45 | 90 | 37 | 76 | 114 | 152 | 88 |

| UNIFREM 400 055 | 55 | 112 | 45 | 90 | 135 | 180 | 110 |

| UNIFREM 400 075 | 75 | 145 | 55 | 112 | 168 | 224 | 140 |

| UNIFREM 400 090 | 90 | 176 | 75 | 145 | 217.5 | 290 | 172 |

| UNIFREM 400 110 | 110 | 216 | 90 | 176 | 264 | *308 | 212 |

| UNIFREM 400 132 | 132 | 260 | 110 | 216 | 324 | *378 | 255 |

| UNIFREM 400 160 | 160 | 315 | 132 | 260 | 390 | *455 | 309 |

| UNIFREM 400 200 | 200 | 396 | 160 | 315 | 472 | *551 | 390 |

| PNOM | - Nominal motor power |

|---|---|

| INQ | - Nominal output current of the converter for variable load |

| INK | - nominal output current of the converter for constant load |

|---|---|

| INK60 | - nominal output current of the converter that is equalled 1,5 x InK for the duration of 60 s each 10 min |

| INK2 | - maximal output current of the converter that is equalled 2 x InK for the duration of 2 each 15 s |

| *INK2 | - maximal output current of the converter that is equalled 1.75 x InK for the duration of 2 each 15 s |

| Type of the converter | height [mm] | width[mm] | depth [mm] (without control panel) | depth [mm] (with control panel) |

|---|---|---|---|---|

| UNIFREM 400 011 ÷ 018 | 550 | 189 | 274 | 290 |

| UNIFREM 400 022 ÷ 037 | 700 | 194 | 274 | 290 |

| UNIFREM 400 045 ÷ 090 | 880 | 356 | 285 | 300 |

| UNIFREM 400 110 ÷ 132 | 1125 | 430 | 295 | 330 |

| UNIFREM 400 160 ÷ 200 | 1425 | 430 | 295 | 330 |

| Type of the converter | weight [kg] |

|---|---|

| UNIFREM 400 011 | 18 |

| UNIFREM 400 015 | 18.7 |

| UNIFREM 400 018 | 21 |

| UNIFREM 400 022 | 25.9 |

| UNIFREM 400 030 | 27.7 |

| UNIFREM 400 037 | 29.5 |

| UNIFREM 400 045 | 66 |

| UNIFREM 400 055 | 70.5 |

| UNIFREM 400 075 | 71.3 |

| UNIFREM 400 090 | 78 |

| UNIFREM 400 110 ÷ 132 | 100 |

| UNIFREM 400 160 ÷ 200 | 130 |

| Input voltage range: | 3 x 380 - 415 V ±10% |

|---|---|

| Input frequency: | 47 to 63 Hz |

| Output voltage range: | 3 x 0 to 100% of input voltage |

| Output frequency: | 0 ÷ 500 Hz |

| Efficiency of the converter: | more than 98.5 % |

| Analog inputs: | 4 programmable analog inputs (Options: 0 ÷ 20 mA , 4 ÷ 20 mA , 0 ÷ 10 V , 2 ÷ 10 V) |

| Digital inputs: | 6 digital programmable inputs 1 digital safety input EN 13849-1 class 3 software adjusted control voltage ( + 24 V or 0 V ) |

| Digital outputs: | 3 programmable relay outputs |

| Analog outputs: | 3 analog programmable outputs 0 ÷ 20 mA or 4 ÷ 20 mA |

| Starting motor torque: | to 200 % Tn (according to the type of motor) |

| Electronic protection against: | overcurrent, overvoltage, undervoltage, short circuit protection, ground fault protection, converter overtemperature, motor overtemperature |

| Cooling: | forced air cooling by built-in fan |

| Electromagnetic compatibility (EMC): | Built-in RFI filter to industrial environment according to EN 61000-6-4 |

| Elimination of higher harmonic components of voltages and currents | built-in three phase choke lowers harmonic currents, extends lifetime of power capacitors, protects converter against voltage peaks |

| Permissible ambient temperature during operation: | +1 °C to +40 °C (EN 50178), optional (special version) -10 °C to + 40 °C |

| Relative air humidity: | ≤ 90 % without corrosive and explosive gases, without water vapor and condensates |

| Degree of protection: | IP20, IP55 possible in enclosure-based modification |